A 737 freighter failed to pressurise because a cargo depressurisation switch had been left on after “unauthorised use”, the ATSB has found.

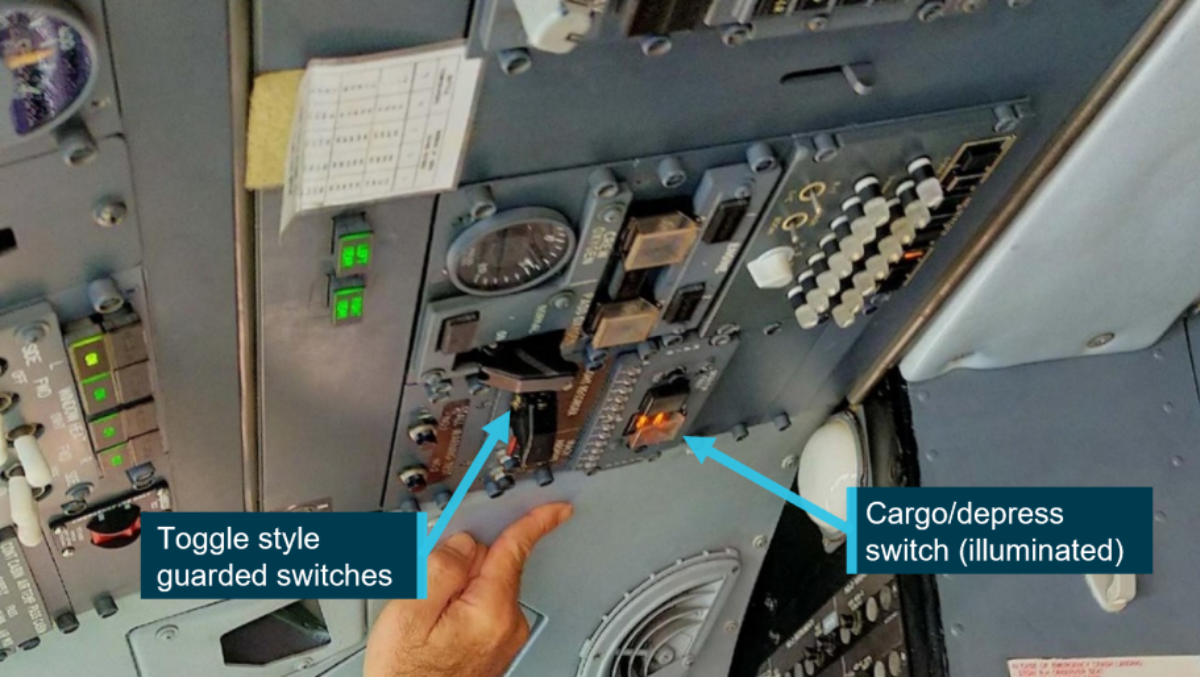

The Airwork-operated plane was forced to turn back to Darwin in November 2021 after the guarded cargo/depress switch – usually used to assist with removal of smoke in the main cargo deck during a smoke event – was left on by a maintenance engineer during pre-flight preparation, who had used it to try to cool the flight deck.

“Using the switch in this manner was not authorised, but it had become normalised by the operator’s staff in Darwin, where there was no ground support equipment to provide external cooling,” said ATSB’s Dr Michael Walker.

“Even though this practice had become normalised, there were insufficient risk controls in place to ensure that the aircraft would be returned to the correct configuration prior to departure.”

After take-off, the flight crew observed the aircraft did not pressurise as expected. After stopping the climb at 11,000 ft, the flight crew began to descend to 10,000 ft, during which time a cabin altitude warning alert occurred.

Once at 10,000 ft, the crew completed required checklist actions, but were unable to establish control of the pressurisation. Subsequently the equipment cooling fan failed, the electronic flight information system reverted to a monochrome display output, and the weather radar failed. The crew made the decision to return to Darwin for an uneventful landing.

The ATSB investigation found a pre-flight check of the switch was not incorporated into the operator’s flight crew operating manual, despite the aircraft’s cargo conversion operations manual stipulating it as a requirement.

Since the incident, the operator issued communications to its staff to immediately cease the unauthorised practice, and remind staff to only operate equipment in accordance with approved documentation.

Additionally, the operator commenced a review of operational documentation and completed incorporating the requirements of the operations manual supplement.

“This incident highlights the risks associated with undertaking unauthorised practices and using equipment in a manner other than for its intended purpose,” Dr Walker said.

“Without formal assessment of its efficacy or its potential for unintended consequences, combined with no documentation of training, there is no assurance that an unauthorised practice would be carried out consistently or safely.”