Quickstep Aerospace Services (QAS) opened its doors in February 2021 as a wholly-owned subsidiary of Quickstep Holdings Limited (Quickstep) – a complementary fit to their aerospace design and manufacturing operations based at Bankstown Airport in Sydney. QAS operates from its world-class MRO (maintenance, repair and overhaul) facility located at Tullamarine Airport, in Melbourne, Australia.

Using leading-edge equipment and state-of-the-art MRO technology and people, QAS manage complete repair solutions on a wide range of composite and metal bonded, as well as conventional metal aircraft structures and mechanical components for both commercial and defence operators. QAS drives customer value through responsiveness, high-quality standards, fast turnaround times and attractive pricing.

QAS carries several Part 145 regulatory approvals (CASA, FAA, EASA, DASA), which is complemented by CASA 21M and DASA 21J along with ISO9110; ensuring an integrated, high-quality and fully compliant service can be provided to both our commercial and defence customers.

Tim Gent, executive general manager QAS, believes, “Our mission is to provide customer valued solutions through a world-class facility and maintenance program that delivers quality repairs at a competitive price, delivered on time and directly aligned to customer need.”

Quickstep is working toward a carbon-neutral future, offsetting scope 1 and 2 greenhouse gas emissions associated with our business in accordance with the Australian Climate Active Program. With strategies in place to drive a sustainable business model and achieve carbon neutrality, we are proud to offer a world-class commercial MRO right here in Australia and reverse recent trends which have resulted in reduced capability due to the continued offshoring of this type of work.

While the pandemic continues to cause supply chain disruption across the global MRO network, it provides QAS with the opportunity to work collaboratively with customers across both commercial and defence to deliver a solution that shortens the supply chain and delivers higher fleet availability at a lower cost. Australia’s domestic borders are re-opening (with increasingly less risk of re-closure), and airlines are bringing aircraft back online with domestic and international flying planned to exceed pre-COVID levels.

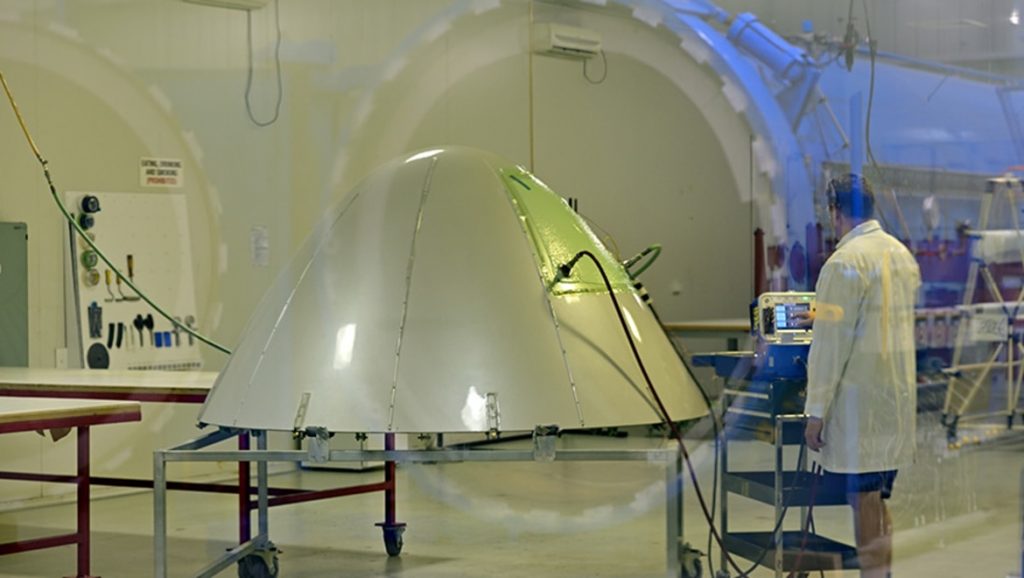

QAS prides itself on understanding the customers’ needs and works together to enable a value-based outcome. QAS will establish and hold the required materials to minimise turn time and enhance our customer’s asset utilisation. The facility is fully equipped to carry out extensive and complex component repairs and includes such assets as an autoclave, clean room, large paint booth and a full range of non-destructive testing equipment available. With world-class facilities come world-class people, with a renewed emphasis on skills development and workforce growth to develop long-term sustainable operations.

QAS is well-positioned to deliver as a short–supply-chain MRO provider to Australian and regional operators. The rapid evolution of the new QAS facility to establish a broader set of platform certifications is underway to maximise its reach across the airlines sector in partnership with the Government of the State of Victoria. With an emphasis on building strong partnerships with key airlines and defence operators, allowing for better-integrated planning between MRO provider and operator, QAS believe customers will see a mutual, value-based benefit from contracting much more MRO onshore.