The ATSB has released its interim factual report into the uncontained failure of a Rolls-Royce Trent 900 engine on Qantas A380 flight QF32 last November, confirming that a manufacturing issue ultimately lead to the failure, but not in the exact area first under suspicion.

The interim report notes that the intermediate pressure (IP) turbine failed when a manufacturing fault in the machining of an oil feed pipe resulted in a fatigue crack that in turn led to an internal oil fire and the subsequent explosive uncontained failure.

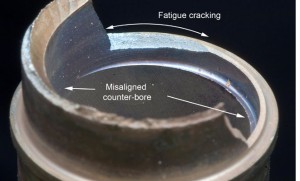

However, notes the interim factual report, “Since the ATSB’s Preliminary Report was issued, analysis of the oil feed pipe fracture surface has progressed and the investigation team has a better understanding of the failure mechanism. Technical reviews to date of the available evidence have established that the location of the fatigue cracking that was depicted in Figure 9 of the Preliminary Report is not the area of interest. The area of fatigue cracking and misaligned counter bore is now understood to be as shown in Figure 1 below [see image opposite].”

The report also notes that there were three different oil feed pipe standards in the IP turbine module case (module 51) of Trent 900 engines in service at the time of the accident, and that not just the 42 engines with the same standard early – FW48010 – oil feed pipe as on the failed QF32 engine were at risk of the machining issue and had to be removed from service for inspection, but that 10 subsequent FW59326 and one FW64481 oil feed pipe standard fitted engines too had to be removed from service due to “oil feed pipe wall thicknesses of less than the Rolls-Royce stipulated minimum acceptance limit of 0.5mm.”

In all, 53 affected engines had to be removed from different operators’ A380s for inspection.

“The ATSB, in conjunction with the UK AAIB and Rolls-Royce, is examining the circumstances and missed opportunities with the potential to have detected the reduced wall thickness and offset counter bore of the oil feed pipe prior to, during and after the manufacture of the module 51 assemblies,” the report reads.

The ATSB says that due to the complex nature of the investigation, it won’t release a final report into the incident until May 2012. Its continuing areas of investigation includes examining airframe and systems damage, including “their effect on the aircraft’s handling and performance and on crew workload”.

The full interim report can be viewed here.

Christine Negroni

says:The engines are an issue yes, but the airplane needs a closer look too. http://christinenegroni.blogspot.com/2011/05/australians-simulate-airbus-380-near.html

ACT

says:I tend to disagree, any aircraft exposed to an uncontained engine seazure (disintegration) of this magnitude, would have at the very least been reduced to the levels of automation that QF32 did, and I believe most aircraft would have been torn to shreads.

I suspect that the vast majority of Australians are unable to realise how close Qantas and Australia got to the largest single aircraft disaster. We are talking millimeters and minutes here, and one reason it didn’t end as a firey crater was the pilots extensive experience and professionalism. This quality is something Australians take for granted, not realising

ACT

says:That other countries envy our safety record.

Apologies for the split post.